|

EXPANSION OF CLEANER PRODUCTION ACTIVITIES THROUGHOUT THE ASIAN AND PACIFIC REGIONS OF RUSSIA 15-18 March 2004, Kuala-Lumpur, Malaysia. The 3rd Asia-Pacific Roundtable for Cleaner Production. Joint Plenary report "Expansion of Cleaner Production Activities Throughout the Asian and Pacific Regions of Russia" |

|---|

| ON MAIN ENGLISH PAGE |

|---|

| Eleonora Barnes – US EPA, Alexander Tsygankov – Director, RNCP Centre, Robert Dyer – US EPA, Larissa Yanchik – RNCP Centre |

|---|

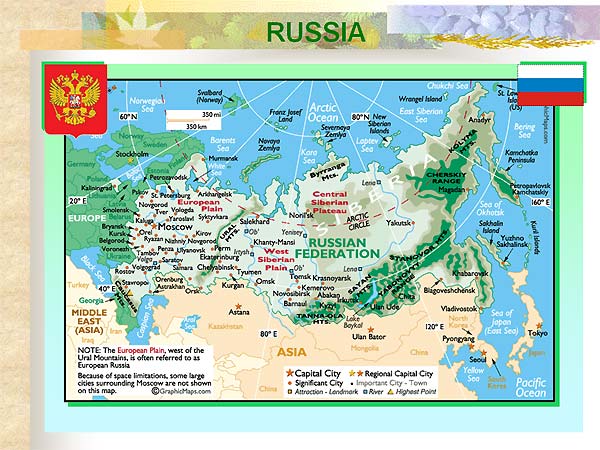

The Russian-Norwegian Program for Cleaner Production was established in 1994 by the joint Russian-Norwegian Commission on Environmental Cooperation. The same year it was also adopted by the Barents Euro Arctic Council. At the beginning, the Center received substantial support from Norway. Currently, the practical implementation of the Program is fully managed and implemented by the Russian-Norwegian Cleaner Production Center (RNCPC) located in Moscow. At the beginning, the Center received substantial support from Norway. Currently, the practical implementation of the Program is fully managed and implemented by the Russian-Norwegian Cleaner Production Center (RNCPC) located in Moscow.RNCPC develops its own curriculum. Training courses are taught by certified Russian engineers and company advisers in co-operation with their Norwegian colleagues. The training courses consist of modules on economics, business, and investment analyses. Also special modules are being developed to target specific needs of each facility, for instance reduction of dioxins/furans emissions, or reduction of hazardous substances including persistent organic pollutants in the waste generated by the industrial facilities. RNCPC offers a variety of programs to address regional needs and requirements, targeting specific branches of industry, as well as special programs. Cleaner Production Training of consists three Phases: Cleaner Production Training, Financial Engineering and Environmental Management Systems. Phase 1, Cleaner Production Training consists of four sessions as follows: (1) Introduction, (2) Cleaner Production Principles, (3) Development of diploma thesis (proposals for environmental improvements), and (4) Successful presentation and defense of their proposal by each participant. Classes end with the Graduation Ceremony, during which each successful participant receives a diploma. (Phase 1 consists of 3 classroom sessions of 3 days each and graduation session of 2 days). Sessions are scheduled six weeks apart. During these intervals, instructors from the Cleaner Production Center conduct site visits and work individually with each participant to identify and evaluate opportunities to achieve cleaner production objectives. Phase 2, Financial Engineering Training consists of 2 classroom sessions of 3 days each. Session 1 focuses on: (1) Evaluation of economic data for proposed projects in support of business plan development and (2) Fundamentals of investments. Session 2 focuses on preparation of feasibility studies and business plans. Phase 3, Environmental Management System Training Program consists of 4 classroom sessions of 3 days each to be conducted quarterly. Between sessions, instructors from the Cleaner Production Center conduct site visits and works individually with each participant to identify and develop project ideas to meet the program objectives. The RNCPC adopted an aggressive outreach program. The Center’s personnel call regional and city officials as well as the management of industrial facilities throughout Russia introducing the program, and also offering to conduct informational seminars. Also, as mentioned above, instructors regularly visit the sites and work individually with each participant. In the European part of Russia, the Nordic Environment Finance Corporation (NEFCO) is an active participant in the program. They established a credit line for financing of the cleaner production proposals. Business proposals are being reviewed by NEFCO’s experts and business loans are provided at a favorable interest rate of 6%, for up to US $250,000, with a payback period of up to three years. (Note: Russian facilities are not yet quite used to the culture of bank financing. However, the need for bank loans for industrial development grows.) Nine years of conducting the Cleaner Production Program in Russia has resulted in practical implementation of thousands of small environmental projects. The majority if these projects are being self-financed by the facilities themselves.  For the first several years, the Cleaner Production Center focused its activities on the European part of Russia. However, since 2001 the geographical area has expanded into the Asian part of Russia. This is happening because most of Russia (66%) - that part from the Ural Mountains to the coast of the Pacific Ocean - is located in Asia. About 28 million people inhabit the Asian part of Russia. Administratively, the area consists of 21 Federal entities - Republics, Territories, Regions and Districts. This area is rich in natural resources - oil, coal, gas, ores of black and nonferrous metals, and wood - and the corresponding industries are steadily expanding due to the respective demands for each. Industrial activities include oil extraction and refining, chemical, metallurgical, and pulp and paper industries, heat and power production, transportation, municipal services and the processing of agricultural products. Much of the Asian part of Russia is in the Arctic. Large pollution-producing industries are located there. As a result, major industrial areas in this Asian Arctic part of Russia have become “hot spots” of significant toxic and hazardous waste pollution. These “hot spots” are having a harmful effect on ecosystems in the Arctic and neighboring Asian Pacific regions. Atmospheric transport of these pollutants from Russia affects the environments of bordering Asian countries as well as the United States. In particular, there are significant emissions of sulfur dioxide from the enterprises of nonferrous metallurgy in Norilsk (3 million tons), and these emissions as well as carbon monoxide and nitrogen oxides are having an impact on the environment of many countries in the Asian and Russian Arctic regions. Industrial pollution in this part of the world is a growing concern for member-counties of the Arctic Council. The Arctic Council was formed as a confederation of like-minded countries, which share a common concern for the health of the peoples and environment of the Arctic. RNCPC became an active participant in the Arctic Council activities, especially in the Arctic Council Action Plan (ACAP) Working Group, one of seven Working Groups under the Arctic Council. The first Cleaner Production Project implemented under the ACAP Program was "Implementation of Cleaner Production, Eco Efficiency and Environmental Management Systems at the Norilsk Mining and Metallurgical Company in the arctic city of Norilsk". This program was funded by the U.S. Environmental Protection Agency (the U.S. EPA) and the Norwegian Pollution Control Authority. This Program was implemented in the Asian part of Russia and targeted the polar branch of the Norilsk Nickel Mining and Smelting Company. Forty-seven experts have participated in the Cleaner Production training thus far, and this work is continuing. The first Cleaner Production Training Program at the "Norilsk Nickel" industrial facility started in February 2002. At the first graduation session, twenty-one participants were awarded diplomas. This program resulted in the development of thirteen low-cost projects. These projects did not require outside investments, and many of these projects are currently being implemented by the company. When implemented, these projects could result in annual savings of over $350,000. Four projects, with a projected annual savings of US $70,000 were implemented during the course of study. The remaining projects are scheduled to be implemented by the end of 2004. The expected annual environmental gains at Norilsk after implementation of these thirteen projects are as follows:

Lessons learned from the Norilsk Nickel Program todate. The analysis indicated that Cleaner Production Training Program taught the participants to think about saving resources. Cleaner Production Training taught the participants that each unit of an industrial process could develop and implement best available technologies and use best environmental practices to reduce operational costs and environmental impacts. Training only twenty-one participants in Cleaner Production principles and techniques is not sufficient for such a large Company as Norilsk Nickel. (Norilsk Nickel currently employs over 85,000 workers). This is only the beginning of their Cleaner Production Program. A company the size of Norilsk Nickel needs to train 200-250 experts, who could join together in efforts to implement Cleaner Production projects and also promote compliance with international certification standards. Currently two more Cleaner Production Projects, sponsored by the USEPA, are being implemented in the Russian Northwest. These projects target the reduction of persistent organic pollutants in the Arctic regions, such as dioixins/furans, focus on the specific industries such as Arctic marine transportation and Maintenance Companies in Murmansk and Severodvinsk. Both projects are in progress. The Cleaner Production Program is expanding to the Russian Far East beginning with the Krasnoyarsk Region where dioxin emissions from metallurgical, pulp and paper and timber processing industries present significant health risks to the local population and beyond via transboundary transfer. Informational seminars have already been conducted in the Republic of Yakutia, and the Krasnoyarsk and Tomsk Regions – in the Asian part of Russia. In Vladivostok, we plan to implement the program in industrial facilities producing large amounts of toxic and hazardous wastes. Challenges of Implementing the Cleaner Production Program in the Asian - Pacific Region of Russia are as follows. Increasing development of the economy in the Asian part of Russia in many respects depends on corresponding changes in industrial policy at the government level in Moscow. Cleaner Production, pollution prevention, waste minimization, and recycling practices must play an important part in this process. The industrial facilities of concern are located in Southern Siberia, where the great rivers (Ob, Yenisei, and Lena) originate. Persistent organic pollutants such as PCBs, dioxins and obsolete and prohibited pesticides and metals such as mercury, lead, cadmium and arsenic are being discharged into these rivers by many industrial and agricultural facilities. Siberian rivers carry this toxic waste, via trans-boundary transfer, into the Arctic Region where it accumulates in the fragile Arctic bio-system. Intensive development of the oil and gas industry in the region of the Sea of Japan and Ohotsk (in the area of Sakhalin Island) cause concern over the environmental effects on the Pacific Region. In Primorskij Krai, Vladivostok Region, measures need to be taken to prevent the pollution of the ocean, the rivers, and the lakes, especially in the border zone with China. Industrial activities of the shipyards require special attention. The Irkutsk region requires a comprehensive cleaner production review of technological processes to address problems of atmospheric emissions from the oil refining, chemical, pulp and paper industries, as well as nonferrous metallurgy, heat, power and other industries. These emissions negatively impact the Arctic environment as well as the environments of Mongolia and China. The Basic Directions of Cleaner Production in the Asian-Pacific Region of Russia. A review of the efficiency of implementing cleaner production programs in the Asian-Pacific Region of Russia suggests that it may consist of separate programs for different territories or Regions, and it will require the assistance of local experts:

|